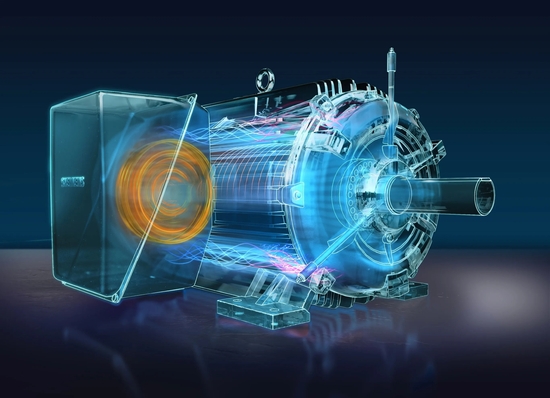

Electric motors with high efficiency reduce the impact on the environment and energy costs

Electric motors are among the key segments of a whole range of industries. We use them in industry, logistics, commerce and households. It is therefore not surprising that there are several categories of electric drives. One of the most important is electric motors with high efficiency.

These electric motors are designed to not only convert electrical energy into mechanical energy, but to be as efficient as possible, which significantly reduces costs and environmental impact. These are highly sought-after attributes these days, whether in industries or in individual households.

Key benefits of using high-efficiency electric motors:

Energy cost savings

Compared to conventional electric motors, a high-quality drive with high efficiency can reduce energy consumption by 20 to 50%. Thanks to this, companies and households save on energy. In the case of electric motors in households, the saving is not as fundamental as in industry, however, even households can save units up to tens of thousands of crowns per year.

Reducing environmental impact

High efficiency electric motors produce less carbon emissions than conventional motors. Especially in the case of industrial companies, it is a significant reduction of the impact of these activities on the environment. In the case of individual households, the reduction in emissions is significantly lower, but even here it is a fundamental shift towards the protection of nature and the environment.

E.g. the US government estimates in one of its latest reports that the use of high-efficiency electric motors in US territory alone in household appliances can reduce carbon emissions by up to 20 million tons annually. Globally, the figures will be significantly higher.

Long service life of the electric motor

High efficiency electric motors are designed to last significantly longer in operation and without the need for major maintenance than conventional drives, significantly reducing the cost of regular servicing or the frequency of purchasing new equipment.

Industrial use

In industrial applications, high efficiency electric motors are used in a wide variety of applications. As part of production, we can find them, for example, in production lines, various machines or in presses. They are also widely used in logistics - they drive warehouse trucks, forklifts or belt conveyors.

In agricultural fields, these drives are used in agricultural machinery, pumps or fans. Electric motors with high efficiency can also be found in energy, construction, healthcare or public services. Their purpose is the same everywhere – they improve operational efficiency, optimize energy costs and reduce the impact on the environment.

Household use

High-efficiency electric drives are also used in our homes. They are found in washers and dryers where they drive drums and pumps. Dishwashers, refrigerators, freezers, steam extractors, fans - the performance of all these appliances is usually taken care of by high-efficiency drives.

In the Czech Republic, since 2015, manufacturers and importers of electric motors with an output of more than 1.1 kW have been obliged to deliver to the market only electric motors with an efficiency of at least 90%. This obligation also applies to electric motors used in households.